Product Information

Helpful information about our products

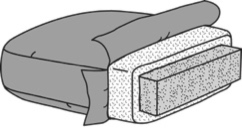

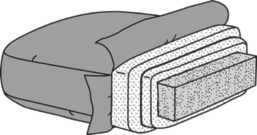

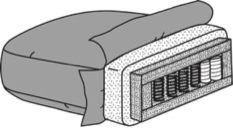

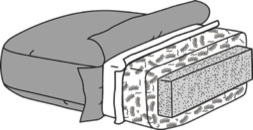

Cushion Construction

Back Cushions

All semi-attached and loose pillow backs are filled with 100% Dacron polyester fiber. On selected styles, covers are “pocket sewn” to retain shape. Frequent “fluffing” is recommended to maintain proper appearance. Selected tight back styles are constructed of urethane foam or 100% needle punched polyester fiber.

Seat Cushions

The loss of resiliency is not to be confused with normal fatigue, which occurs in all foam as a result of use aging. Frequent turning of the cushions is recommended to maximize life expectancy.

The Comfort Plus cushion is standard in selected styles only. A minimum 1.8 density, high resilience, high performance polyurethane foam provides this cushion with extra support, durability and constant comfort.

The Comfort Blend cushion is available in selected styles only. It is a 2.0 density, high-resilience foam core with a 1” wrap of ultracell foam.

The Comfort Spring cushion is available in selected styles only. This handcrafted cushion features individually wrapped coil springs laminated top and bottom to a high-performance polyurethane foam and then wrapped in a .25-ounce polyester fiber. Seating comfort is superb.

The Blendown cushion is available in selected styles only. This cushion is a foam core wrapped in a blend of feather and fiber encased in a down proof casing.

The Synthetic Blend cushion is available in select styles only. It is a 1.8 density foam core wrapped in a micro denier siliconized fiber strand that offers maximum loft and resilience. It replicates natural down in feel, structure, and appearance. The fiber wrapped core is encased in a down proof ticking.

The Alfresco Plus cushion is standard in outdoor styles only. It is a 1.8 density, high resilience, high performance polyurethane foam that provides this cushion with extra support, durability and constant comfort. The foam core is antimicrobial to resist molds and mildew.

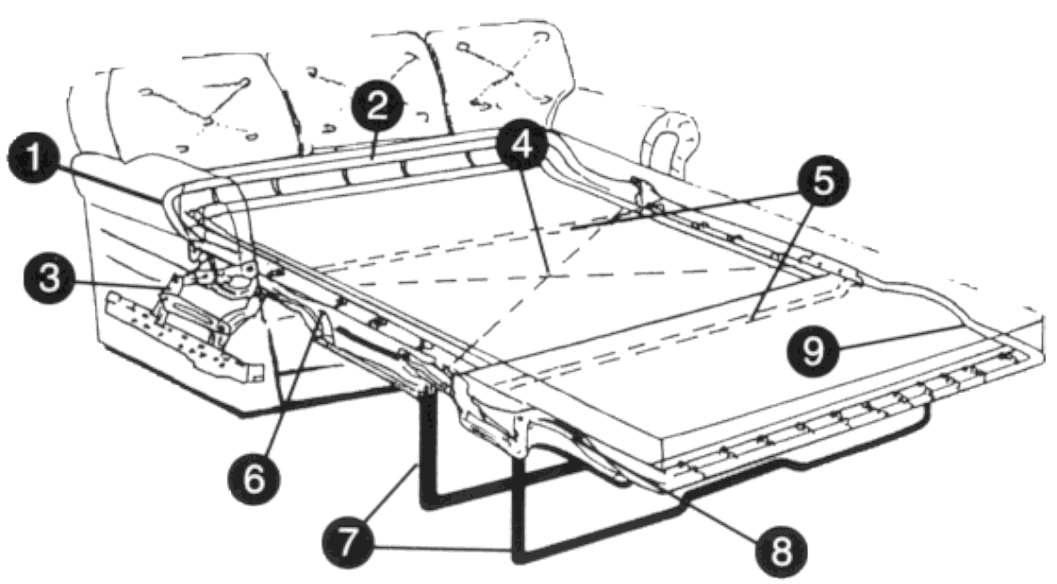

Sleeper Mattress & Mechanism Information

Mattress and Sleeper Mechanism Specifications for All Braxton Culler Sleeper Sofas

The luxurious damask ticking is richly quilted top and sides to provide outstanding comfort

Queen mattress measures 72" long by 60" wide

Full mattress measures 72" long by 52" wide

Twin mattress measures 72" long by 32" wide

Overall depth of ALL sleeper frames from back of frame to front of mattress is 93”

Custom Innerspring Mattress features 5” standard no charge

Luxurious Damask Ticking

Lace tufting—Eliminates shifting and humping of padding

Thick quilted top for added comfort

Extra thick polyfoam topper

Fiber padding eliminates “coil feel” non-allergenic, odor free, mildew-proof

Quilted side border, just like premium residential bedding

300 oven tempered coils std.

Heavy duty bottom cloth eliminates abrasion

Personalized label

Memory Foam Mattress

Our memory foam mattress gives more support with less thickness and bulk, the mattress is 3lbs, Memory Foam 2.75” E 31 with 1.8 Density Polyurethane Foam. The mattress finishes at 5” thick.

Air Dream Mattress

The result is a sleep surface that provides correct support and also cushions the body with an upholstered layer of air. This innovative air-over-coil technology looks and feels like a premium luxury mattress. Easily inflates in just 45 seconds. Pump integrated to mattress.

Standard Mechanism Features No Charge 2 year warranty

TV Headrest

Contoured head section

Advanced Linkage design

Sleep support cross wires

Recessed cross ties

AXH Rivet Design

Dual tubular legs

Contoured seat

Tubular steel perimeter

Anti tilt

General Product Information

Upholstery Frame Construction:

Due to the various structured designs of our products, we use a combination of selected kiln-dried hardwood components in combination with 7-ply plywood engineered frames. All stress joints are double-doweled, glued and screwed.

Seat Construction

Sinuous Wire: A sinuous wire spring is used throughout. These springs are fully tempered to provide maximum resilience, more body support, and greater seating comfort for the life of the product.

Wire Permalator: A wire grid is inserted and stapled to frame, covered by a layer of foam and denim. This provides support and seating comfort for the life of the product.

Fabric Information

The following are fabric specifications for tailoring Braxton Culler products:

NOTE: Bench Seats will have a seam if a topped fabric is used.

Only stripes, plaids and center prints are matched.

Back cushions and seat cushions are matched on both sides where the fabric pattern allows.

Inside and outside arms are matched.

Outside backs are matched.

Inside backs to seat cushions to seat cushion borders to skirts are matched.

Kick pleat skirts are pelon lined to provide a neat tailored look.

Braxton Culler is not responsible for dye lot differences for orders that are placed at different times.

A railroaded fabric pattern is one where the pattern runs horizontally from selvage to selvage. This allows one to “unroll” the fabric across the sofa and cut and apply the fabric without seams to a one-piece back. A “topped” also known as an up the bolt pattern is one where the pattern runs vertically from one end of the roll to the other. This necessitates the use of seams for one-piece backs and cushions.

Customers Own Material (COM)

When ordering Braxton Culler furniture in COM fabrics please adhere to the following steps:

Pricing on fabric COM use Grade D pricing. Vinyl pricing use Grade E pricing. Fabrics with heavy vinyl backing that also require breathers use Grade E pricing.

COM yardage requirements for matched fabrics and topped fabrics must be increased over the stated yardage on each individual style. See chart on page 19.

Fabric must be marked with dealer name, order number and date, style number and customer name. Please include the following form with COM.

The customer must inspect all COM fabric. The factory accepts no responsibility and will allow no adjustments on COM. Should the fabric be defective, it will be returned freight collect.

If contrast welts are desired, add 1 yard for chair, 1.5 yards for loveseat & 2 yards for sofa.

Unless specific instructions are provided regarding the application of stripes, vertical, horizontal, or face side of the fabric, it will be applied by the factory at their own discretion without liability for doing so. We will assume that the face side is rolled in. If there can be a question concerning which side is the face side, please attach a cutting showing the face side to the COM form.

COM must be shipped to the factory freight prepaid. Please take note: COM orders are not placed into production until the COM is physically received at the plant. Please have the description of COM on your order, if you don’t have a pattern and color number; a good physical description will suffice.

When multiple fabrics are used, each fabric must be clearly marked as to location or part of the upholstered item.

All fabric is subject to factory approval. Not all fabrics are suitable for upholstery manufacturing.

We will no longer return excess yardage; therefore, please ONLY send the required yardage for items being ordered.

We only accept COM that is a 54” width.

If contrast welts are desired, add 1 yard for chair, 1.5 yards for loveseat, 2 yards for sofa, and 3 yards for headboard.

Still have questions?